Automating defect

Identification In

Solar Panels

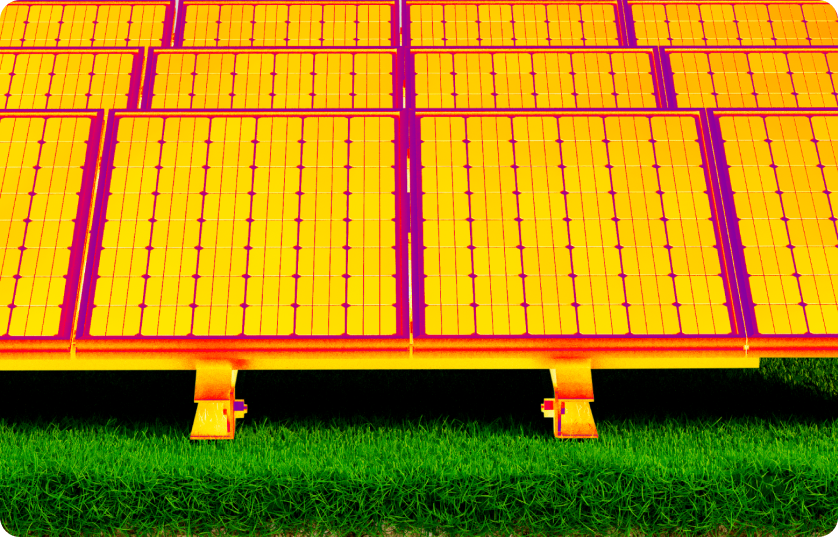

SolarAI is an artificial Intelligence platform that uses our state of the art artificial intelligence algorithms on thermal images to identify defects in solar panels. Utilising drone technology, thermal images of the solar plant are taken; these images are then analysed through our AI model. The model identifies faults and defects in these solar panels and details are sent to ERP for maintenance.

HOW IT WORKS

Solar AI ensures the smooth functioning of solar power plants. Utilising a mix of image generation, image analysis, defect

identification and work order creation, SolarAI ensures that every solar cell and panel functions at its optimal best.

Step 1

Drone Mapping

Drones are used to captue thermal images of the panels of the entire solar acreage. These high-resolution images capture details of each cell and panel.

Step 2

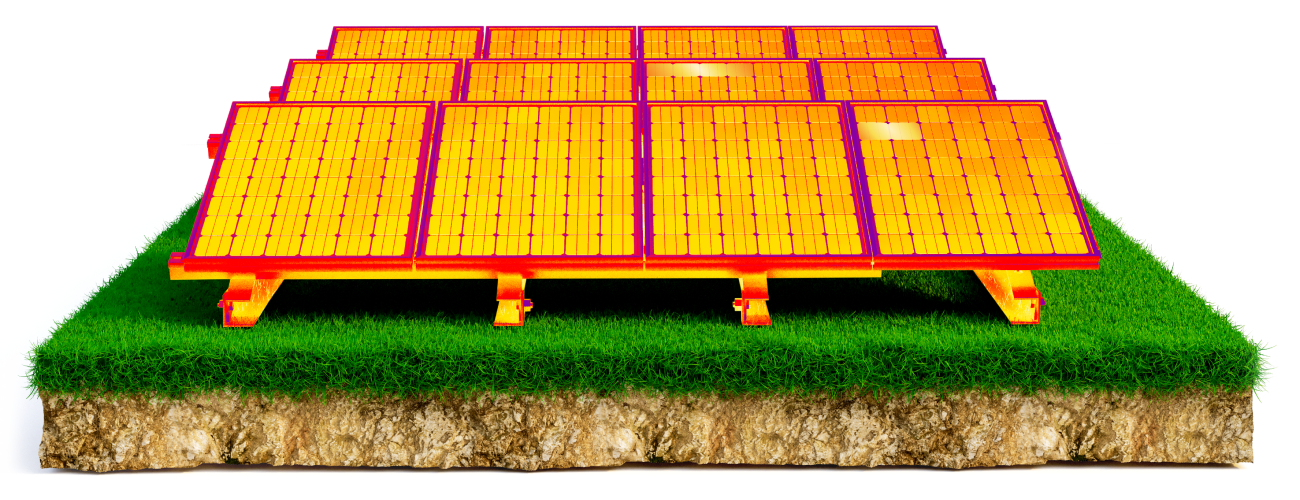

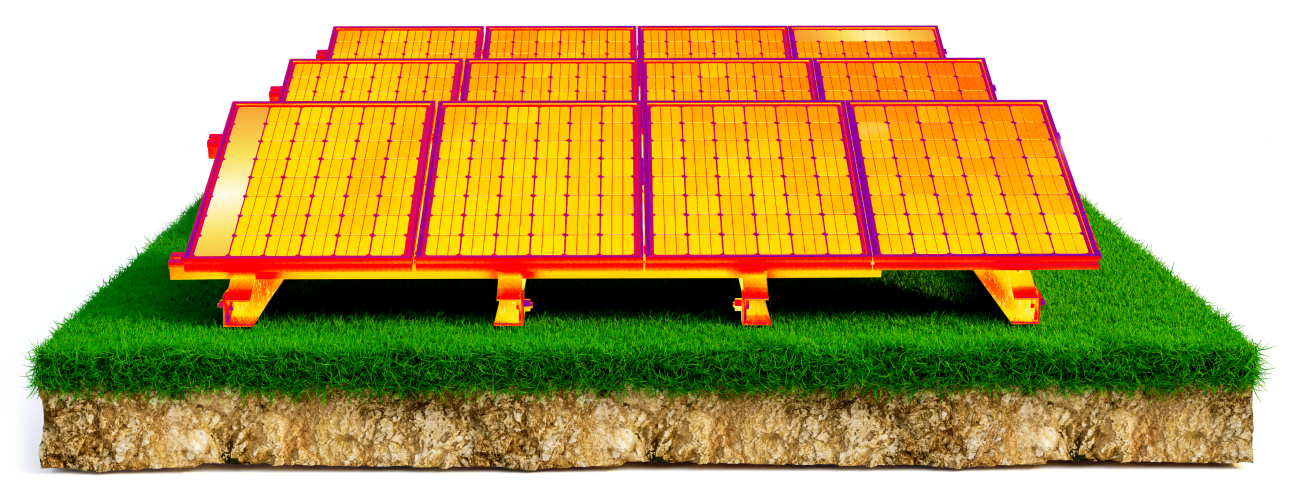

Orthomosaic Generation

Thermal images captured by the drone are stitched together to form an ortho-mosaic layout aligning with the geographic axis of the solar field.

Step 3

Defect Identification

The ortho-mosaics are sliced into smaller layers and passed through our state-of-the-art AI model to identify defective solar panels. Defects along with their types and corresponding location is identified by the model.

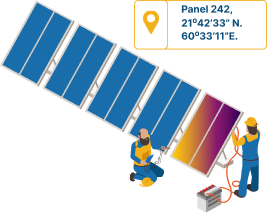

Step 4

Work order Creation

Defect details along with geographic location is sent to ERP to further processing. Solution allows to create maintenance work orders from the UI itself.

Step 1

Drone Mapping

Drones are used to captue thermal images of the panels of the entire solar acreage. These high-resolution images capture details of each cell and panel.

Step 2

Orthomosaic Generation

Thermal images captured by the drone are stitched together to form an ortho-mosaic layout aligning with the geographic axis of the solar field.

Step 3

Defect Identification

The ortho-mosaics are sliced into smaller layers and passed through our state-of-the-art AI model to identify defective solar panels. Defects along with their types and corresponding location is identified by the model.

Step 4

Work order Creation

Defect details along with geographic location is sent to ERP to further processing. Solution allows to create maintenance work orders from the UI itself.

DEFECT DETECTIVE

SolarAI identifies nearly 10 types of defects. Some of the most common defects are

shown below.

1

2

3

4

BENEFITS

Reduction

In efforts to map and identify defects through leveraging drone-based imagery and AI-driven algorithms.

Decrease

In monthly power generation losses due to faster identification of deteriorated or damaged PV panels.

Improvement

In efficiency of identifying deteriorated or damaged PV panels as compared to manual processing.

Savings

In annual labour costs through the elimination of manual inspection and processing.

TESTIMONIAL

CASE STUDY

SolarAI leverages AI based processing to automate the defect identification in

solar panels for large solar power plants.